There are thousands of materials available for use in engineering applications. Materials can be of natural origin or synthetically processed and manufactured. According to their chemical nature, they are broadly grouped traditionally into inorganic and organic materials. Their physical structure can be crystalline, or amorphous. Most materials fall into one of three classes that are based on the atomic bonding forces of a particular material. These three classifications are metallic, ceramic and polymeric. Additionally, different materials can be combined to create a composite material. Composites are combination of materials assembled together to obtain properties superior to those of their simple constituents. Within each of these classifications, materials are often further organized into groups based on their chemical composition or certain physical or mechanical properties. Composite materials are often grouped by the types of materials combined or the way the materials are arranged together.

According to the atomic bonding, materials can be broadly classified into the following groups:

| Metals: valence electrons are detached from atoms, and spread in an 'electron sea' that "glues" the ions together. Metals are usually strong, conduct electricity and heat well and are opaque to light (shiny if polished). Examples: aluminum, steel, brass, gold. |

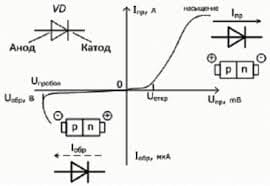

| Semiconductors: the bonding is covalent (electrons are shared between atoms). Their electrical properties depend extremely strongly on minute proportions of contaminants. They are opaque to visible light but transparent to the infrared. Examples: Si, Ge, GaAs. |

| Ceramics: atoms behave mostly like either positive or negative ions, and are bound by Coulomb forces between them. They are usually combinations of metals or semiconductors with oxygen, nitrogen or carbon (oxides, nitrides, and carbides). Examples: glass, porcelain, many minerals. |

| Polymers are bound by covalent forces and also by weak van der Waals forces, and usually based on H, C and other non-metallic elements. They decompose at moderate temperatures (100–400 °C), and are lightweight. Other properties vary greatly. Examples: plastics (nylon, Teflon, polyester) and rubber. |

| Other categories are not based on bonding. A particular microstructure identifies composites, made of different materials in intimate contact (example: fiberglass, concrete, wood) to achieve specific properties. |

Biomaterialscan be any type of material that is biocompatibleand used, for instance, to replace human body parts.

| Materials engineers are involved in the development, processing, and testing of the materials used to create a range of products, from computer chips and aircraft wings to golf clubs and snow skis. They work with metals, ceramics, plastics, semiconductors, and composites to create new materials that meet certain mechanical, electrical, and chemical requirements. They also are involved in selecting materials for new applications. |

| Materials scientists are discovering and creating entirely new types of materials – such as buckyballs and nanotubes, which are very tiny spheres or cylinders made of carbon atoms. To get an idea of the nanoscale, a human hair is about 80,000 nanometres wide. One nanometre is about a million times smaller than the diameter of a pinhead. |

Then there are aerogels, which are extremely lightweight porous materials made almost entirely of air! Nanotechnology is taking materials science into a new dimension, as scientists create new materials atom-by-atom and molecule-by-molecule leading to properties and performance never before imagined.

To choose a material with the best performance for a particular application, we will need to consider the properties of the available materials. Properties are the observed characteristics of a sample.

When designing anything in general, an engineer has to keep in mind the product triangle, containing the materials, designing and processing. Some materials aren’t suitable for a certain design, whilst other materials may be too difficult to process to meet certain design requirements.

A materials cost is also generally a limiting factor. Understanding the entire processing sequence is critical to accurately evaluating the true cost of a material.

2015-08-13

2015-08-13 550

550