A. Filleted Transition Regions

Values of fillet radius r

| d | rmax |

| Over 18 to 30 | 1.6 |

| Over 30 to 50 | 2.0 |

| Over 50 to 80 | 2.5 |

| Over 80 to 120 | 3.0 |

end of the table 10.2

Values of K s and K t

| t/r | r/d | K s at s ul (MPa) of | K t at s ul (MPa) of | ||||||

| 0.01 | 1.55 | 1.6 | 1.65 | 1.7 | 1.4 | 1.4 | 1.45 | 1.45 | |

| 0.02 | 1.8 | 1.9 | 2.0 | 2.15 | 1.55 | 1.6 | 1.65 | 1.7 | |

| 0.03 | 1.8 | 1.95 | 2.05 | 2.25 | 1.55 | 1.6 | 1.65 | 1.7 | |

| 0.01 | 1.9 | 2.0 | 2.1 | 2.2 | 1.55 | 1.6 | 1.65 | 1.75 | |

| 0.02 | 1.95 | 2.1 | 2.2 | 2.4 | 1.6 | 1.7 | 1.75 | 1.85 | |

| 0.03 | 1.95 | 2.1 | 2.25 | 2.45 | 1.65 | 1.7 | 1.75 | 1.9 |

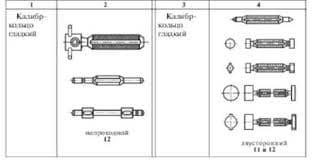

B. Values of K s and K t for Keyed portions of Shafts

| s end, MPa | K s for keyseats cut with | K t | |

| End mills | Side mills | ||

| 1.60 | 1.40 | 1.40 | |

| 1.90 | 1.55 | 1.70 | |

| 2.15 | 1.70 | 2.05 | |

| 2.50 | 1.90 | 2.40 |

C. Values of K s and K t for Splined and Threaded Portions of Shafts

| s end, MPa | K s for | K t for | |||

| Splined portions | Threaded portions | Parallel-sides splines | Involute splines | Threaded portions | |

| 1.45 | 1.80 | 2.25 | 1.45 | 1.50 | |

| 1.60 | 2.20 | 2.45 | 1.50 | 1.65 | |

| 1.70 | 2.45 | 2.65 | 1.55 | 2.10 | |

| 1.75 | 2.90 | 2.80 | 1.60 | 2.39 |

D. Values of K s/ Kd and K t/ Kd at Interference-Fit Joints

| Shaft diameter d, mm | K s / Kd at s ul, (MPa) of | K t/ Kd at s ul, (MPa) of | ||||||

| 2.5 | 3.0 | 3.5 | 4.25 | 1.9 | 2.2 | 2.5 | 3.0 | |

| 3.05 | 3.65 | 4.3 | 5.2 | 2.25 | 2.6 | 3.1 | 3.6 | |

| 100 up | 3.3 | 3.95 | 4.6 | 5.6 | 2.4 | 2.8 | 3.2 | 3.8 |

In our case the critical section of the shaft is a section where a bearing is mounted so we will use as stress concentrator interference fit. Then

from the table 10.2 D.

from the table 10.2 D.

|

|

|

10.3.6. Determine the surface roughness factor KF. For that we use Fig.10.3.

10.3.6. Determine the surface roughness factor KF. For that we use Fig.10.3.

Fig. 10.3. Values of KF: 1 - polished portions; 2 - ground portions;

3 - portions made with finish turning; 4 - portions made with rough turning

It is necessary to note that the portion of the shaft where a bearing is installed should be ground while the shaft portion for a toothed wheel is made with finish turning.

Thus portion of the shaft where a bearing is installed grounded and KF = 0.9.

|

|

10.3.7. Determine factor Kd, that takes into account absolute dimensions of the shaft cross-section. For this purpose we use Fig.10.4.

|

Thus we have carbon steel without stress concentrators and Kd = 0.82.

10.3.8. Determine safety factors in terms of bending and torsion

;

;

.

.

10.3.9. Determine the safety factor of the shaft at the critical section

;

;

Allowable values of the safety factor [ S ] are given in table 10.3.

2015-08-21

2015-08-21 307

307